Boats - Cleaning, Polishing, and Long-Term Ceramic Coating

Boats and water sports vehicles embody a maritime lifestyle—designed to enjoy the freedom of the water and create unforgettable experiences. However, this very environment that provides incredible adventures also presents significant challenges to their materials and surfaces. Gelcoat, marine paint, boat lacquer, wooden decks, fabric canopies, as well as rubber and seals, are constantly exposed to the elements: saltwater and freshwater, intense UV radiation, fluctuating temperatures, and mechanical stress.

Over time, these factors can leave visible and invisible marks. Gelcoat loses its shine and becomes porous, making the material more susceptible to dirt and microorganisms. Painted surfaces fade and may start peeling, wooden decks dry out or become brittle, and fabric canopies deteriorate faster due to moisture and dirt. Rubber and seals, which are crucial for functionality and water resistance, degrade due to UV radiation and saltwater, becoming brittle and losing their elasticity.

Regular and proper maintenance is therefore essential to extend the lifespan of boats and water sports vehicles and to preserve their value. This is not just about maintaining their visual appearance but also about preventing structural damage and ensuring their functionality. This guide explains how boats and water sports vehicles can be effectively cleaned, polished, and protected long-term with advanced ceramic coatings.

Pre-Cleaning

Pre-cleaning is a crucial step to effectively remove organic deposits such as algae and other contaminants. Ideally, an alkaline or effective pH-neutral pre-cleaner should be used. These cleaners are sprayed onto the cooled surfaces and, after about 5 minutes of dwell time, rinsed off with a strong water jet or a pressure washer. If necessary, this process can be repeated and enhanced by using brushes or microfiber cloths.

Recommended products for this step include Gtechniq Citrus APC W5, which is particularly effective against organic dirt, and Gtechniq APC W2, known for its versatility. Both cleaners help to optimally prepare the surfaces for the next care steps.

Removing Mineral Deposits

After pre-cleaning, the focus shifts to removing mineral deposits. Acidic cleaners are used, specifically designed to dissolve limescale and other mineral residues. The cleaner is applied section by section, and its effect can be enhanced by using brushes, microfiber cloths, or wash mitts. After treatment, the surface should be thoroughly rinsed with water to completely remove any residues.

The recommended product is W9 Waterspot Remover from Gtechniq, known for its efficiency in removing stubborn water spots and mineral deposits without damaging treated surfaces.

Hand Washing and Removing Final Contaminants

The cleaning process concludes with a thorough hand wash to eliminate deeply embedded contaminants. The boat is first washed from top to bottom with a wash mitt to remove coarse dirt. Suitable shampoos include Gtechniq Marine UV Wash, which provides UV protection, or GWash, which is ideal for surfaces with ceramic coating.

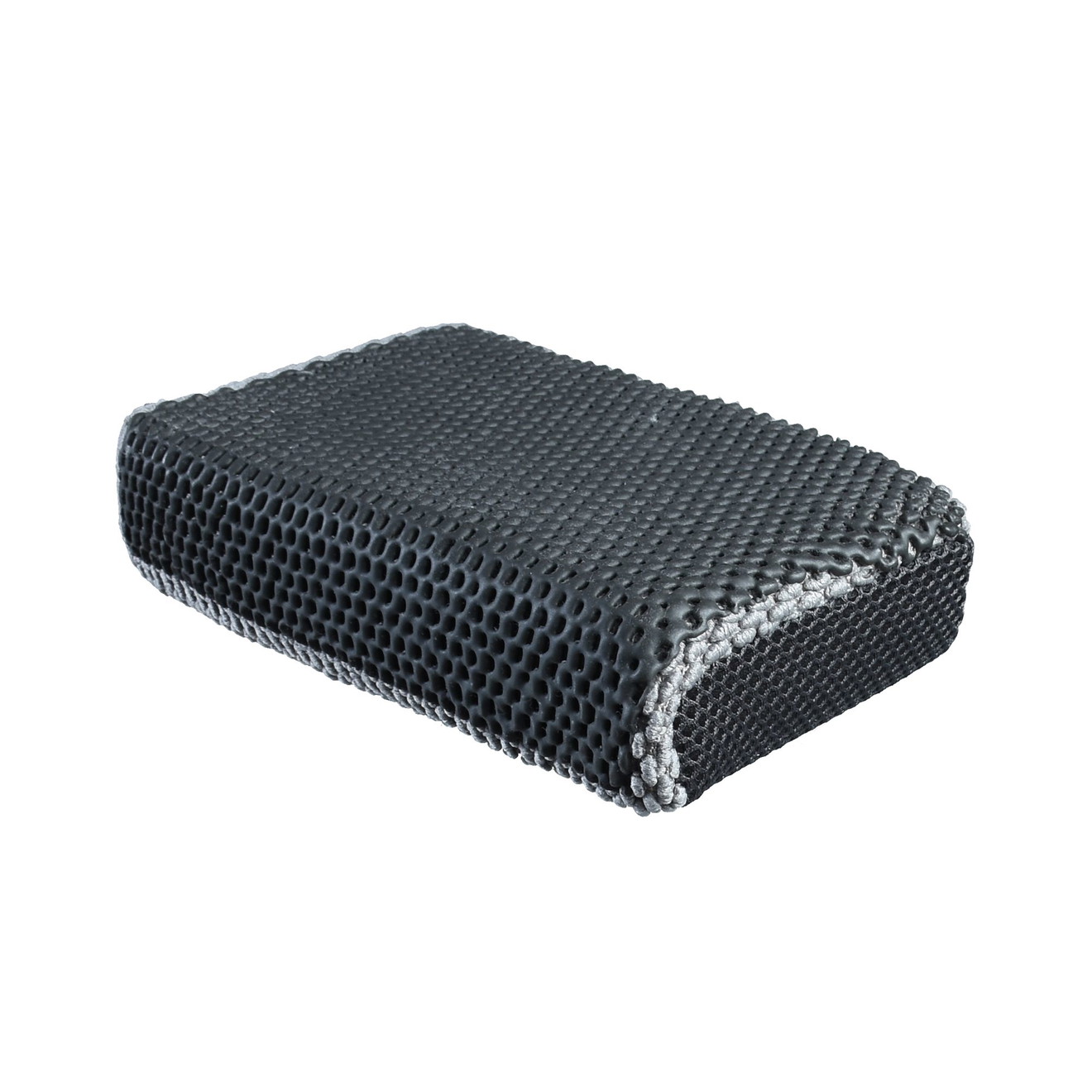

This is followed by another wash using a clay towel or a clay pad, such as “The Mesh Clay Towel” or “The Mesh Clay Scrubber.” This step ensures that any remaining surface dirt is removed, which could otherwise affect the polishing results. The combination of specialized clay and thorough cleaning prepares the surface perfectly for polishing and sealing.

Polishing Boat Paint and Gelcoat

Rotary vs. Dual Action Polishing

When polishing boat paint and gelcoat, two main techniques are used: rotary and dual action polishing. Rotary polishers move exclusively in a circular motion, offering high cutting power but requiring experience, as improper use can cause holograms or even damage. Dual action polishers combine circular rotation with an oscillating motion, making them easier to handle and particularly suitable for beginners.

Recommended Polishing Compounds

Excellent results can be achieved on boat paint, whether gelcoat or other finishes, with DynaOne from Dynabrade, which delivers outstanding results in just one step. For a multi-step approach, 3D ACA 500 or ACA 510 are ideal, followed by 3D One, which can be used both as a cutting and finishing polish.

General automotive polishes are not recommended, as they are not specifically designed for the demands of boat paint. The recommended polishes have been tested on marine coatings and provide optimal results.

Polishing Pads and Sponges

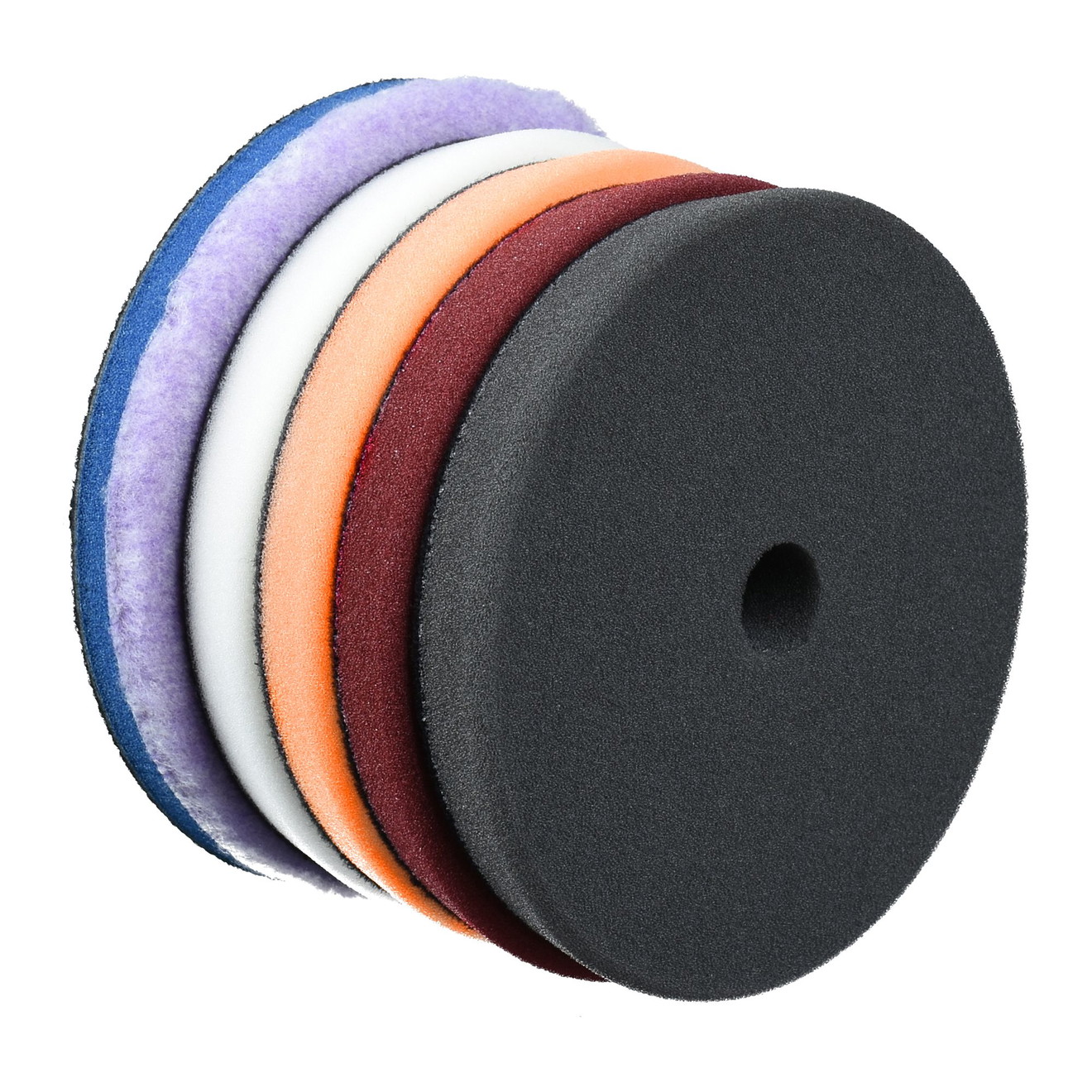

For polishing boat paint and gelcoat, various polishing pads and sponges are available, depending on the condition of the surface. Very aggressive microfiber or wool pads are best for severe defects, while medium-hard foam pads are ideal for finishing and minor defects.

Recommended polishing pads:

- Lake Country 125mm Microfiber Cutting Pad – for severe defects and high cutting power.

- DP Pro 125mm Hybrid Wool "Angry Red" – a wool pad with high cut for heavy defects.

- DP Pro Therminator 125mm Medium Cut Orange – ideal for moderate defects and even removal.

- DP Pro 125mm Therminator Intermediate Blue – perfect for minor defects and finishing.

The choice of the right pad depends on the condition of the surface and the desired results. For the best results, the polishing pad should be cleaned regularly and replaced when necessary.

General Polishing Guidelines

When polishing boat paint and gelcoat, work in 50 x 50 cm sections to ensure uniform coverage. 2-3 cross passes per section are sufficient to achieve optimal results.

After polishing, excess polish residue should be wiped off with a microfiber cloth. To optimally prepare the surface for sealing, the paint must be degreased using a 50/50 isopropyl alcohol-water mixture or a specialized surface cleaner like Gtechniq Panel Wipe. Degreasing is crucial to ensure that the subsequent coating adheres chemically and permanently to the gelcoat.

Long-Term Protection with Ceramic Coatings

After polishing and thoroughly degreasing the paint or gelcoat, the surface is pristine and ideally prepared for long-term sealing. Unlike traditional waxes or polymer sealants, which last only a few months, ceramic coatings provide protection for several years.

The UK-based company Gtechniq has pioneered innovative products in this field. For sealing, a two-step process is recommended:

1. Gtechniq Ceramic Base Coat

The Base Coat is applied as a foundation layer and offers several benefits:

- Excellent protection against UV radiation, oxidation, and chemical exposure.

- Water-repellent properties (hydrophobicity) for easier cleaning.

- Durability: forms the base for a long-lasting coating.

After applying the Base Coat, a waiting time of at least 8 hours is required before proceeding to the next step.

2. Gtechniq Ceramic Top Coat

The Top Coat is applied as the final layer and enhances the benefits of the Base Coat:

- Extra smoothness for a brilliant, mirror-like finish.

- Increased scratch resistance to protect the surface from mechanical wear.

- Extended durability by sealing the base layer.

Efficiency of the Coating

The ceramic coating is highly efficient. With just 50 ml, approximately 8-12 m² can be coated for long-term protection. This high yield makes the application both effective and cost-efficient.

Thanks to Gtechniq’s advanced technology, the boat remains protected long-term and looks as good as new for years to come.

Microfiber Cloths for Boat Detailing

High-quality microfiber cloths are an essential tool in boat detailing, especially for polishing and sealing. Choosing the right cloth is crucial to achieving optimal results and preventing damage to delicate surfaces.

Reuse and Limitations

Cloths used for removing polishes or degreasing can be reused after thorough cleaning. However, microfiber cloths used for buffing ceramic coatings should no longer be used on delicate surfaces. After application, these cloths contain microcrystals that could cause scratches. They can still be repurposed as general cleaning cloths for non-sensitive surfaces.

Recommended Microfiber Cloths

- Detail Passion Microfiber Cloth Ceramic Buff Splitted Double40 Skyblue: Ideal for removing polishes and degreasing before coating.

- Detail Passion Microfiber Coating Saver V2 Applicator Block: Perfect for even application and buffing of ceramic coatings.

Using the right cloths enhances the quality of the detailing process and effectively protects the boat’s surface.

Sealing Glass and Plexiglass

What applies to boat paint also works excellently for glass and plexiglass. Sealing these surfaces protects against dirt, water spots, and other environmental influences while ensuring clear visibility and easy cleaning.

Recommended Sealants

- Gtechniq G1 Smart Glass: Specifically designed for real glass, this sealant provides long-lasting protection and hydrophobic properties.

- Gtechniq G5: A versatile glass sealant suitable for both real glass and plexiglass and Makrolon. It prevents dirt buildup and makes cleaning easier.

Quick Application Guide

Applying glass and plexiglass sealants is straightforward and delivers impressive results. Both products should be used according to the manufacturer’s instructions to achieve the best performance. For detailed processing instructions, refer to the respective product pages from the manufacturer.

Care and Protection of Fabric Covers

Fabric covers on boats are constantly exposed to sun, water, and dirt. Without proper protection, they can quickly fade, absorb moisture, or become dirty. To extend the lifespan of fabric covers and keep them in optimal condition, sealing with Gtechniq Smart Fabric I1 V3 is recommended.

Benefits of Gtechniq Smart Fabric Sealant

- Water and dirt repellency: The sealant forms an invisible barrier that prevents water and dirt from penetrating.

- Breathability: Despite the protective layer, the fabric remains breathable and retains its natural flexibility.

- UV protection: Reduces fading and protects against harmful UV rays.

- Long-lasting protection: The sealant lasts for an extended period and significantly reduces maintenance effort.

Quick Application Guide

The application is simple: After thoroughly cleaning the fabric cover, the product is sprayed evenly and should be left to dry completely for several hours. For precise processing instructions, refer to the product information provided by the manufacturer.

With Gtechniq Smart Fabric, fabric covers stay not only clean and protected but also look new for years to come.

Care for Plastic and Rubber Components

Plastic and rubber elements on boats, including seals, are constantly exposed to sun, water, and weather conditions. These stresses can lead to cracks, discoloration, and a loss of elasticity. Regular care is essential to prevent such damage and extend the lifespan of these materials.

Recommendation: 303 Aerospace Protectant

303 Aerospace Protectant is a specially formulated product for protecting plastic, rubber, and seals, offering numerous advantages:

- UV protection: Prevents fading and protects against harmful UV radiation.

- Restoration and enhancement: Restores surfaces to a like-new appearance without leaving a greasy residue.

- Water repellency: Forms a protective layer that prevents water absorption and simplifies cleaning.

- Versatile application: Suitable for all plastic and rubber components, including delicate seals.

Quick Application Guide

The application is simple: Apply the product with a clean microfiber cloth or sponge to the cleaned surface and distribute it evenly. Any excess should be wiped off with a dry cloth for a perfect finish. Regular reapplication is recommended to maintain full protection.

With 303 Aerospace Protectant, plastic and rubber components stay not only protected but also retain their appearance and functionality for a long time.

Ongoing Boat Maintenance

To maintain the protection and aesthetics of the boat over the long term, regular maintenance is essential. The focus should be on gentle yet effective cleaning that preserves the coatings.

1. Pre-Cleaning with Gtechniq W5

Regular pre-cleaning can be done with Gtechniq W5 Citrus All Purpose Cleaner. This versatile cleaner removes organic contaminants such as algae, grease, and general dirt without harming the surfaces. The cleaner is sprayed on, allowed to dwell for a few minutes, and then rinsed off thoroughly.

2. Water Spot Removal

For stubborn water spots caused by mineral deposits, Gtechniq W9 Waterspot Remover is recommended. This cleaner effectively removes limescale and ensures a spotless surface.

3. Washing with Gtechniq Marine UV Wash

The final hand wash can be done with Gtechniq Marine UV Wash. This specialized shampoo provides deep cleaning, UV protection, and helps maintain the coating. It is applied evenly with a soft wash mitt and then rinsed off with clean water.

With this ongoing maintenance routine, the boat remains clean, protected, and visually appealing while extending the lifespan of protective coatings.

By following these tips and using the right care products, your boat will be ready for many unforgettable adventures on the water. Whether you're heading out to sea or enjoying a leisurely cruise on a lake, a well-maintained boat always turns heads.

Remember: A well-maintained boat is not only more attractive but also safer and longer-lasting. So, cast off, set sail, or start your engine and enjoy your next voyage! Feel the wind in your hair and the spray on your skin—that's what makes life on the water so unique.

With that in mind: Fair winds and following seas, always keep a hand’s breadth of water under your keel, and get ready to set sail! Let the waves roll and the adventures begin!